When Viktor Hovland needed a putter, he reached out to Ping and worked extensively with their engineering team to create a fully customized PLD DS72 mallet that’s been in his bag for all three of his PGA Tour wins.

“I was using a counterbalanced putter from another manufacturer at that time,” Hovland recalled. “When I signed with Ping in 2019, I really wanted to stay in that look. I’d had a lot of success with it, so it was important to keep some continuity. The milled insert in [the DS72] is something that I much prefer as well. Instead of the ball melting on the face, you can feel the ball a little bit, and it improved my speed.”

Tony Finau enjoyed a similar experience when he made the jump to a wide-body PLD Anser 2D in 2021. Struggling to find a putter offering the ideal blend of stability and consistency, Finau worked closely with Tony Serrano, a senior design engineer at Ping, to pin down a winning combination that quickly helped him break a five-year winless drought and notch his second PGA Tour title at the Northern Trust.

FIRST LOOK: Ping launches Tour-inspired Putting Lab Design (PLD) programBy: Jonathan Wall

“I felt a boost of confidence when I started using the putter,” Finau said. “The guys at Ping worked closely with me on the putter, so I felt comfortable with everything. To see my feedback turned into a fully custom putter was pretty cool. It’s even better that it helped me win almost immediately.”

Hovland and Finau are two of the biggest success stories for a custom program that has the potential to turn the putter industry on its head.

When the PLD program was first introduced several years ago, its main goal was simple: Gather feedback from the best players in the world on potential putter designs that weren’t already in the Ping manufacturing matrix. Some of the feedback eventually led the company to create some of its most popular head shapes, including Hovland’s DS72 and the Prime Tyne — a “winged” mallet that was originally created for staffer Cameron Champ.

“The feedback was important,” says Serrano. “But we also wanted to tell them about some of the things we were hoPing to do with our putters, and how to grow the program. We learned a lot about what we could do with putter design.”

In particular, Ping came to the realization that PLD had legs in the retail space. Tour fittings can be extensive and typically take several hours to conduct, which is part of the reason manufacturers in the putter space have refrained from opening up the experience to the masses. In a phrase, it’s difficult to meet everyone’s needs.

Or, at least, that was the case before the PLD program came along. Having ramped up its manufacturing capabilities, Ping has finally unveiled an ambitious Tour-level putting experience unlike anything that’s been done in the past.

Wall-to-Wall Equipment: How a rarely seen alignment aid ignited Tony Finau’s Ping putterBy: Jonathan Wall

The full PLD custom experience affords golfers the opportunity to be a Tour pro for a day by scheduling either a virtual fitting or a Ping Putting Lab fitting with a master fitter at the company’s Phoenix-based headquarters. The end result from the work done with Ping’s team is a fully customized putter built to your exact specifications, all the way down to the head material (stainless or carbon steel) and face milling.

“We’re pretty comfortable saying that whatever you add to that putter — be it different alignment lines, stamPing, colors — it’s going to be one of a kind. No one else is going to have it out there.”

As you’d expect with a custom program bearing Ping’s name, the fitting process is extensive. Using the PLD iPing putting app and Quintic Ball Roll (at Ping headquarters) in indoor and outdoor settings, your stroke and fitting data are first analyzed to reveal the proper length, loft, lie and grip.

From there, a putter model is eventually selected from 16 different head shapes and numerous neck options, including some that were initially only available to Tour pros.

Each putter can also be fully customized with everything from tungsten weights and face milling to unique finishes, alignment aids, engravings and more. Once the custom selections are made, the putter is then passed along to Ping’s WRX master machinists and club builders to finalize the order.

The entire PLD custom putter experience retails for $1,290 and includes the custom fitting, putter, finish, face milling, alignment lines, shaft, grip, engraving and paint fill.

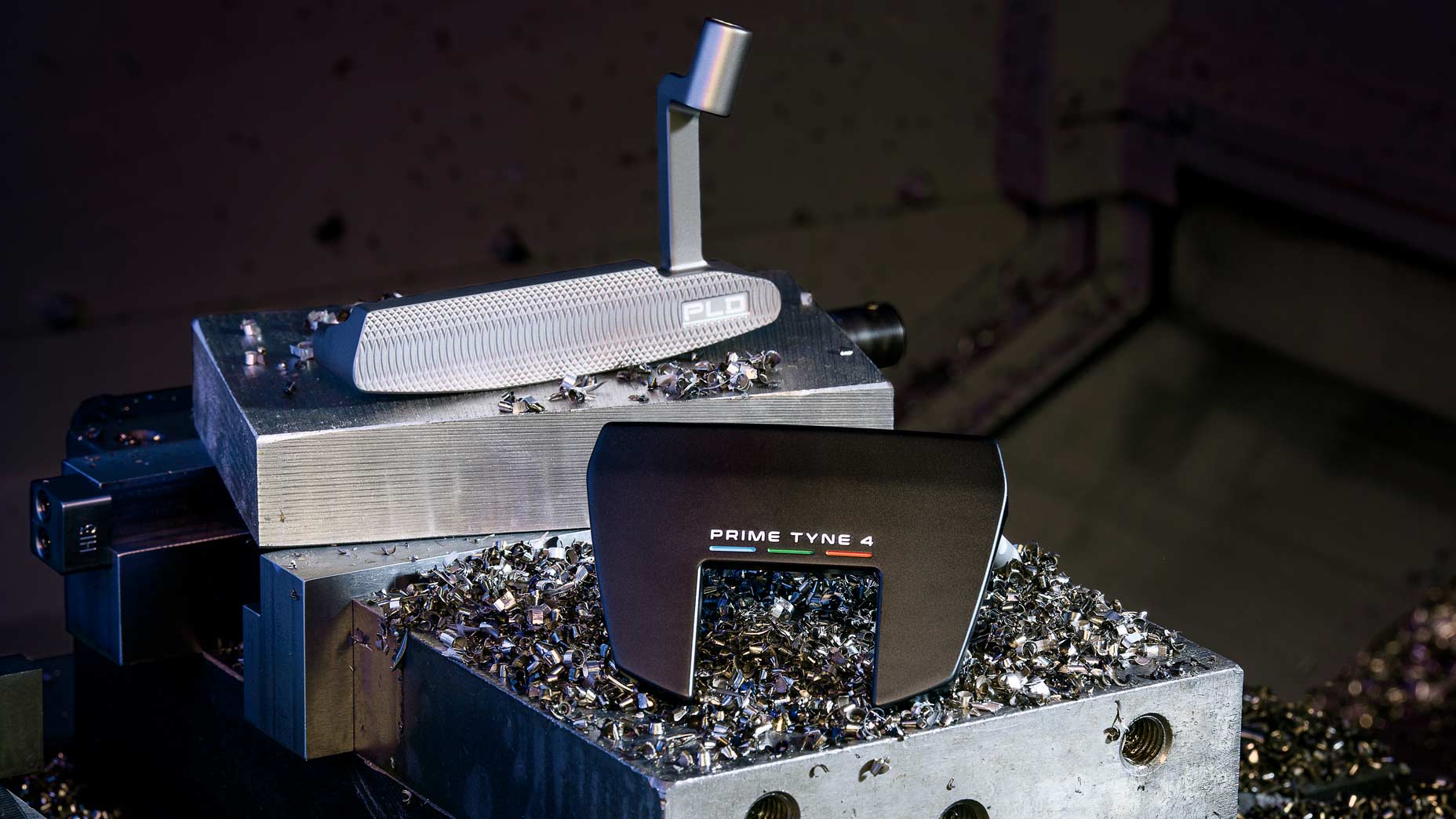

Recognizing that not every golfer can spring for a $1,290 custom putter, Ping also created PLD Milled ($485) to fill an important slot in the putter program. The four Tour-inspired models in the matrix (Anser, Anser 2, DS72, Prime Tyne 4) are fully machined from forged 303 stainless steel and undergo four hours of milling time before coming off the production line.

“It’s all about giving golfers options,” Serrano says. “In the past, most rec golfers weren’t able to get access to Tour putter fittings. We’re trying to change that and give them an experience they’ll remember forever.”

And for your true Ping uber-aficionados? Keep visiting Ping’s website (Pinggolf.com)for limited-edition PLD classics based on the 1955 Anser ($790) in stainless, bronze, carbon steel and “special” finish, which will be available in batches between now and the holidays.