Cobra continues to build on an already impressive 2025 lineup of products with the introduction of the new KING and KING X wedges.

Here are four things to know about the new Cobra wedges.

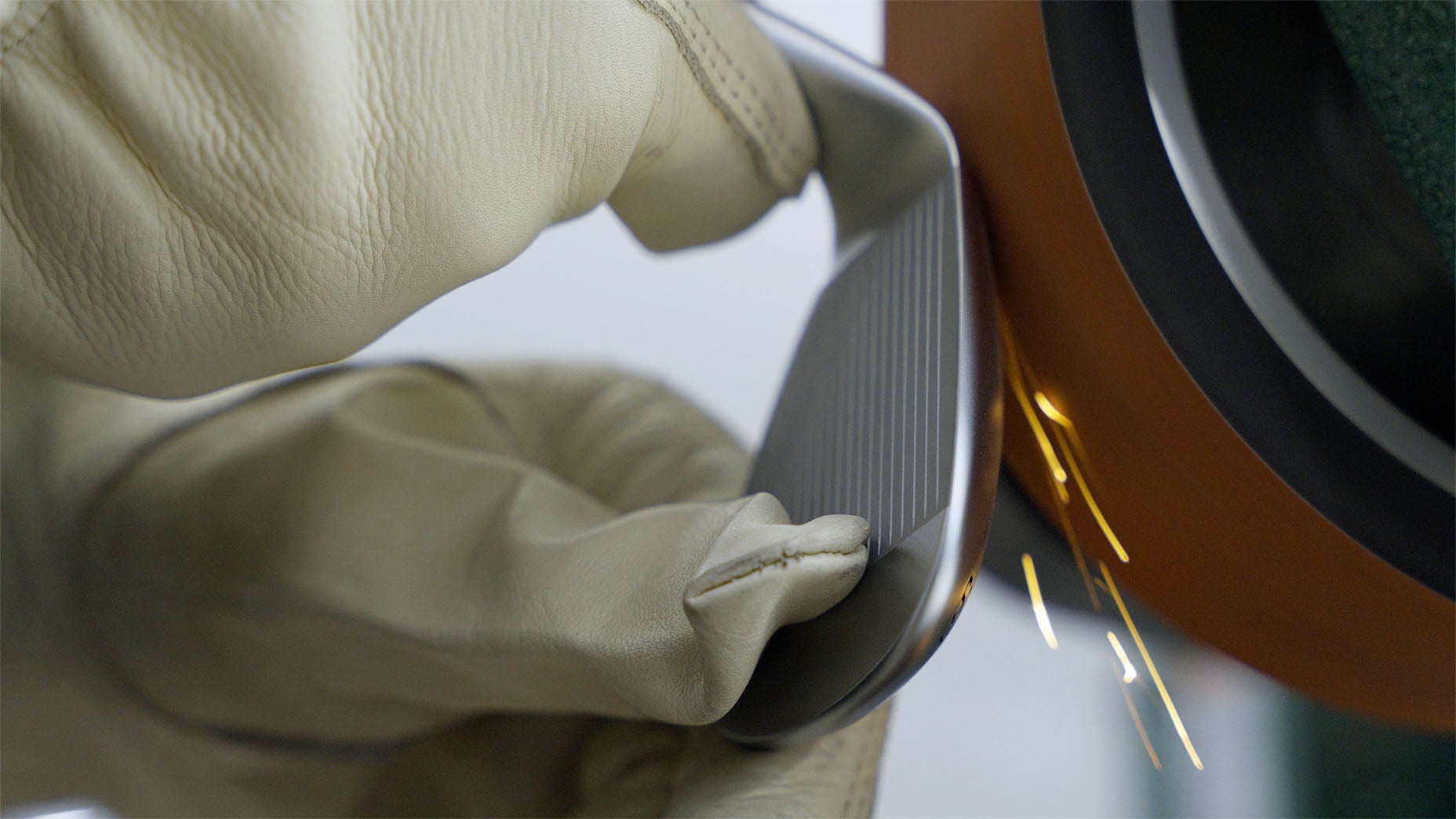

1. Metal Injection Molding

Each KING wedge is manufactured using MIM (Metal Injection Molding) technology. The MIM process allows for exceptionally tight manufacturing tolerances — as much as 50% tighter than conventional cast wedges — and requires less post-production finishing to prep the head before being player-ready.

Each wedge is also heat-treated to nearly 2500 degrees F, leading to a tighter grain structure for a softer feel and enhanced precision.

2. Flight Window Technology

The KING wedge features F.W.T (Flight Window Technology) which positions the CG optimally for each loft. This means stronger lofts fly higher and land softer while weaker lofts fly lower and maintain maximum spin.

Progressive Spin Technology features narrow deep grooves in the lower lofted wedges and wide, shallow grooves in the higher lofted models to optimize spin and control.

3. Four grind options

Four sole grinds are available to fit the full range of players, including DROP (D), WIDELOW (W), VERSATILE (V), and TOUR (T). In addition, the new KING wedges feature a redesigned Cobra Speed Notch in the sole that is 67% larger, claiming to promote more consistent turf interaction through the ground for cleaner contact and more spin.

4. KING X wedges

The new KING X wedge features a forgiving, cavity-back design with a progressive teardrop for game-improving versatility from a wide variety of lies. Like the KING model, the KING X wedges are manufactured using MIM technology and feature a TPU insert for an enhanced feel at impact.

To further improve forgiveness, a deep undercut design allows 20g of weight to be redistributed to the perimeter of the club head, making the KING X more stable on off-center hits.

Price and Availability

Both the KING and KING X will be available at retail on March 6th and will cost $169 each. For more information visit cobragolf.com.

Want to overhaul your bag for 2025? Find a fitting location near you at True Spec Golf.