Welcome to Gear Questions You’re Afraid to Ask, a GOLF.com series where we tackle your hard-hitting club queries.

What’s up with the wave of “boutique” clubmakers that have been popping up? Who makes their stuff? And how do they keep their prices down? — Rich C., Dallas

Since 2020, golf has experienced a boom in participation, and, accordingly, equipment sales have been brisk. This explosion of demand left many established manufacturers and their suppliers pushing supply chains to the brink, which in turn caused delays in getting clubs to consumers. In early 2021, even Ping’s president took to the production floor to help his team assemble clubs.

Against this backdrop, some consumers — both new and old — turned to alternative equipment companies to get new gear faster.

Many of these upstart companies, like Robin Golf or the reincarnated Lynx Golf UK, were founded within the past five years and offer packages, non-customizable sets or partial sets marketed toward new golfers, and promised high value for the price.

Other companies focused on selling only irons and offer a moderate amount of customization of shafts and grips at a slightly higher price, but still well under the starting prices of the major OEMs. Some direct-to-consumer companies offer 4-PW iron sets for as low as $460; Robin Golf’s 13-piece complete set with a bag is $1,199.

Now, to your question, Rich: How do they do it? How can startups create, design and market a line of clubs faster and for less cost than mainstream manufacturers without having an R&D staff with in-house engineers?

Simple: These companies don’t need their own engineers.

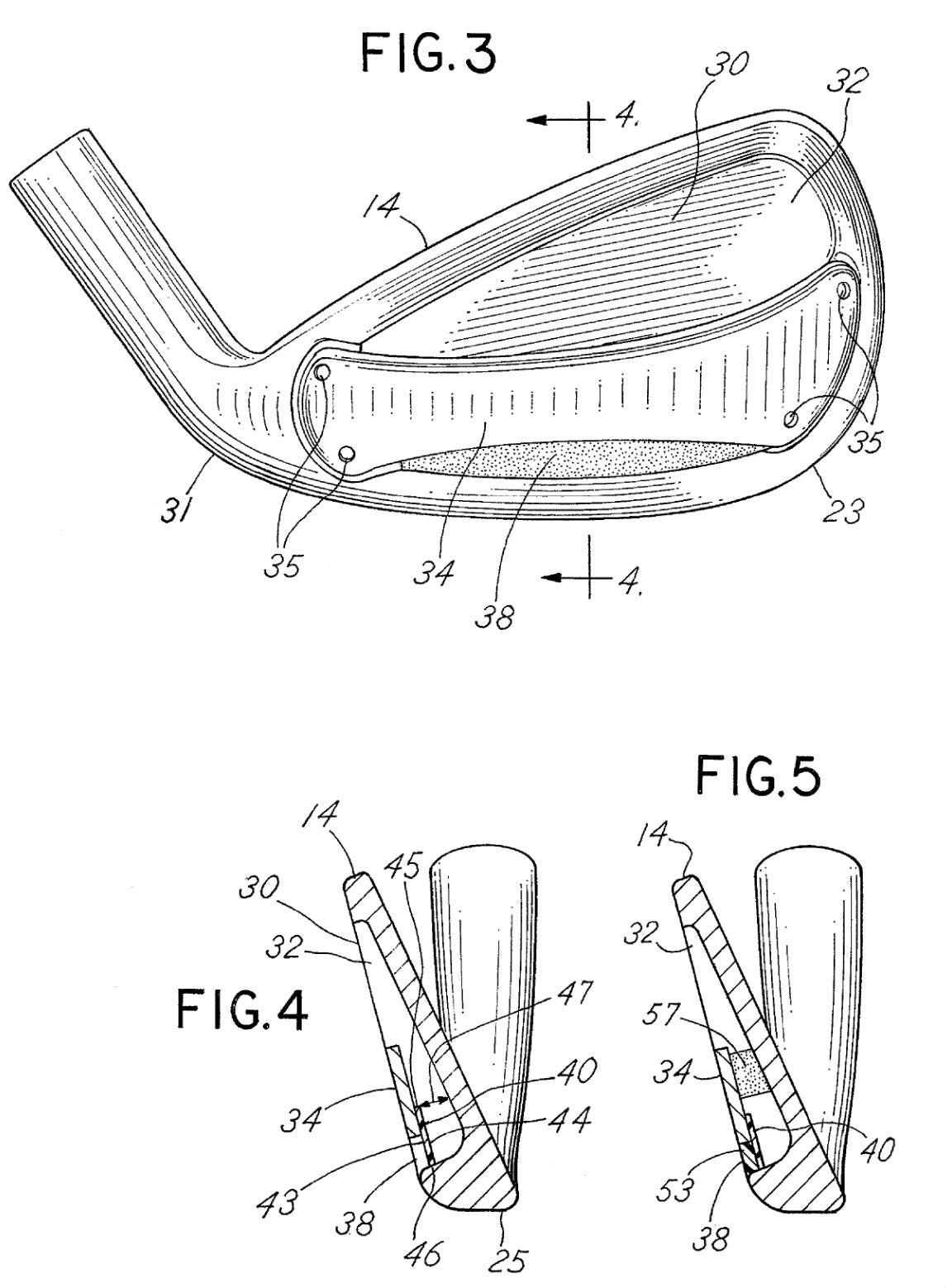

With enough cash in hand, companies can simply order clubs from an overseas manufacturer, or a broker working with a manufacturer, that is already producing market-ready designs. These clubheads, known as “open models,” may be sold to one company as an exclusive, or rebranded and resold to many companies.

Apply your own logo, finish or badge, and — voila! — you are the proud owner of a golf-equipment company.

This practice isn’t new to golf, or to many other industries for that matter. Open-model or white-label production of goods happens with everything from televisions to T-shirts; it’s just a matter of finding the right supplier. A quick Google search will send you down a rabbit hole of white-label goods ready to brand and sell.

Have you ever noticed how many nondescript percussion muscle message guns and golf rangefinders you can find online from various brands that all look remarkably similar? That’s because, at their core, they are.

But aren’t these designs patented?

Yes and no. Although the big OEMs have filing cabinets full of patents, many of those patents have run their course, allowing other manufacturers to follow suit in producing clubs with similar technology — this is why, for example, so many of the putters today resemble a Ping Anser.

There’s also a general lack of intellectual-property protection around basic features of irons, wedges and metal woods, and this is where the brand buyer/marketer can work with an overseas manufacturer to get the features and materials they want in a clubhead, with the goal of staying within the desired price point.

Original designs

Let me make this very clear: These open-model club head designs are not knockoff, counterfeit clubs built with the intention of fooling golfers into thinking they are buying a club from a big brand. They are original designs manufactured with the intention of being rebranded and sold to companies around the world. What consumers ultimately pay is determined by the quantity of the components ordered from the manufacturer, possible volume discounts passed on to the buyer and the quality of the components used to build the clubs, including shafts and grips.

If any consumer can buy an industrial-quality steel shaft for $7.99 and a grip for $3 from a component supplier in North America, imagine what a large company with buying power can do when purchasing thousands of unbranded components to be assembled overseas — it’s the economy of scale.

Why prices fluctuate

The reason you see such a variation within the final sales price from company to company, especially if those companies are assembling in North America instead of overseas, is that more options available to the end consumer lead to higher prices, based on companies having to purchase and hold inventory.

The most important part of this for consumers to understand is the reason these products cost less than those from the major manufacturers is that these companies aren’t spending the same amount of money on research and development or searching out new premium materials with which to build clubheads. They are simply using available technology, and any development

Are you planning an equipment overhaul in 2023? Find a fitting location near you at GOLF’s affiliate company True Spec Golf. For more on the latest gear news and information, check out our latest Fully Equipped podcast below.costs are split among the many companies and amortized over the life of the production cycle.