Welcome to another edition of the Fully Equipped mailbag, an interactive GOLF.com series in which our resident dimplehead (a.k.a., GOLF’s managing editor of equipment, Jonathan Wall) fields your hard-hitting gear questions.

For wedge play, where feel is of the utmost importance, why do more pros prefer milled over forged? — Bob, Michigan

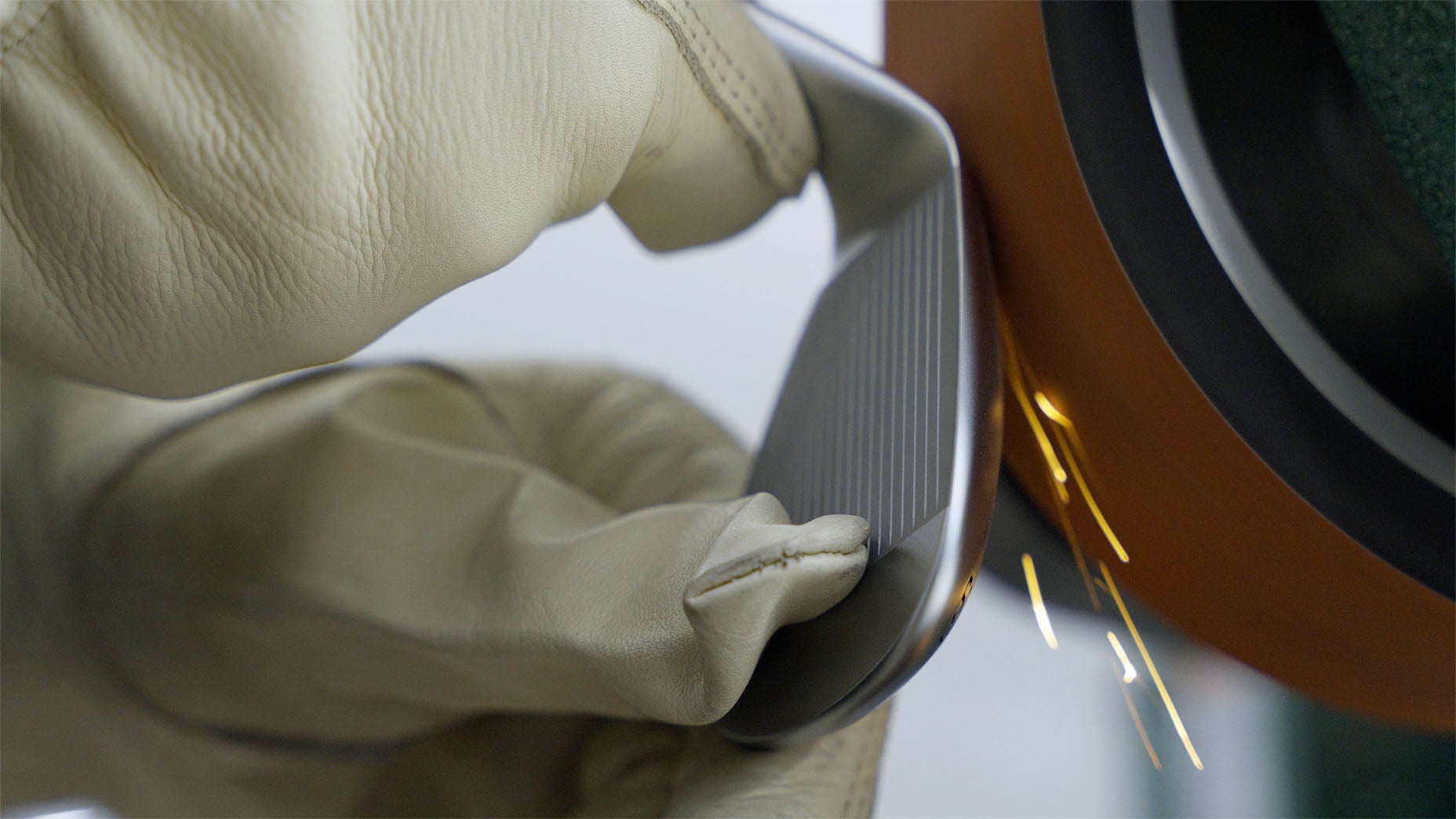

Let’s start with the most important bit that needs to be cleared up: Milling is a finishing process that removes excess material to create a precise sole grind or groove geometry. Forging is a forming process that takes a solid billet of steel through a myriad of steps — using heat, pressure and tooling dyes — to refine the hunk of metal into a club. One is a machining process; the other is a forming process.

Sure, you probably see the words “Forged” and “Milled” on a club and assume they are different designs. Since you mentioned the word “feel,” my mind goes straight to the more common comparison: cast versus forged. We actually covered this question last year for the mailbag, but it’s worth reheating for golfers who don’t know the differences. One is taking a solid and reforming it in a forging process, while casting takes something molten and shapes it.

For example, Titleist’s Vokey SM10 is cast from 8620 carbon steel, while PXG’s Sugar Daddy is forged three times from 8620 carbon steel. Both wedges feel exceptional, but they undergo different processes and have factions that swear one “feels” better than the other. Feel is subjective, just to be clear, so there’s no right or wrong answer here.

“The majority of tour pros are going to prioritize turf interaction, shape and how it suits their eye and moves through the turf,” said True Spec’s VP of tour and education, Kris McCormack. “Feel is subjective, whether it be a cast club, forged club or milled club. Or even Callaway’s new Opus wedge that’s MIM (Metal Injection Molded) technology. There’s so many different variables that go into a wedge fitting, and for a tour player who has access to anything out there, their feel is going to be associated with consistency of weight, turf interaction and playability around the greens.”

According to Gene Parente, Golf Laboratories’ founder, robotic testing with forged and cast products revealed little in the way of performance differences.

Titleist Vokey SM10 Raw Custom Wedge

View Product

“There’s a little bit of a loft difference [during testing], but I was like, Oh, wow, wait a minute. What’s going on here with these categories? I was so confused,” Parente said of the results. “It’s not about performance, it’s about feel. Titleist did a test where they quantified it. They tested different grooves of different wedges. As they hit around 1,000 balls, consistency started to decrease.”

If you prefer a buttery feel, forged wedges provide that in spades. But it usually comes at the cost of groove wear. Parente noted that “forged wedges don’t last because the material is substantially softer, so the grooves don’t last nearly as long.”

However, that’s never a problem for pros who swap wedges whenever they see a decline in spin and launch characteristics. Cast wedges generally found at retail have a plating covering the carbon steel that keeps the head from rusting and extends groove life. Depending on who you ask, the chrome-nickel plating makes the wedge “feel” firmer at impact. However, that’s entirely based on the golfer and their feel preferences.

Some believe removing the plating and using a raw wedge elicits a softer feel at impact, but it comes at the expense of accelerated wear (rust) and grooves that tend to wear down faster than a plated head. (And before you ask, rusty wedges don’t spin more than a plated option.)

As for why pros prefer milled wedge products, it generally comes down to the ability to create a very specific shape and make additional modifications, if need be, that fit their eye.

“Whether the club is forged, cast, MIM’d or milled — the feel, performance and playability all come into play,” McCormack said.

Want to overhaul your bag for 2024? Find a fitting location near you at True Spec Golf.