Welcome to GOLF.com’s ClubTest Proving Ground, where managing equipment editor Jonathan Wall and senior equipment editor Ryan Barath put the latest designs and groundbreaking technology in the equipment space to the test on the range and the course.

The tools: Cobra Limit3d (7-iron; N.S. PRO MODUS³ Tour 105X shaft), Ping i230 (7-iron; N.S. PRO MODUS³ Tour 105X shaft)

The test: To determine if a 3D-printed iron with a $3K price tag can live up to the hype.

The results: Sticker shock is a good way to grab a golfer’s attention. Throw a $2K-plus price tag on a set of irons and watch what happens. Curiosity usually takes hold, which is exactly what happened in 2016 when PXG introduced its original 0311 irons at $400 per club. The polymer-filler, hollow-cavity iron was unlike anything in the industry.

Fast forward to 2024 and nearly every major equipment manufacturer has a hollow-cavity players-distance iron.

Who’s to say if Cobra’s 3D-printed Limit3d will follow a similar path, but it’s interesting to note the two irons share some similarities. A sky-high price tag ($3K per set), limited availability and groundbreaking technology. It also helps that Bryson DeChambeau is using a set of 3D-printed printed irons with custom bulge and roll baked in.

This could be the future of iron design. Or it could be a fad.

To get a better handle on Limit3d’s bona fides, I pitted the 3D design against my Ping i230 gamers to see how they stacked up. While the iron looks like a blade at address — it’s slightly more compact than i230 — the lattice design on the back of the head creates a weight reduction that makes it possible to add upwards of 100 grams of tungsten within the heel and toe.

More tungsten means better ball speeds on severe misses. As Mike Yagley, Cobra’s VP of innovation and AI, noted during a recent conversation, he saw minimal ball speed loss on toe misses during his initial testing. Just to put that observation into perspective, it’s natural to see anywhere from 13-18 yards of distance loss with similar better-player models, according to GOLF’s robotic data.

It almost sounded too good to be true.

However, based on the numbers I saw during my own testing, the hype is for real. Let’s start with the launch monitor numbers from Foresight’s GCQuad launch monitor.

Cobra Limit3d: 131.1 mph (ball speed) | 20.4 degrees | 6,652 RPMs | 179.8 yards (carry)

Ping i230: 127 mph (ball speed) | 20 degrees | 6,396 RPMs | 175.3 yards (carry)

Cobra unveils first consumer-ready 3D-printed irons. Here’s how they workBy: Ryan Barath

The numbers above are an average of the 8 shots I hit with each iron. The numbers tell an interesting story that highlights the importance of getting fit. The Limit3d was 4 mph faster than my i230s with a similar launch angle and 300 RPMs more spin. If I spent the time finding the ideal shaft, I might be able to squeeze a few more yards out of the Limit3d.

Not only was the iron faster, it produced impressive ball speed numbers on toe strikes, too. At one point during the testing session, I hit several balls out on the toe to see how it performed. For the most part, ball speed dropped roughly 2 mph on even the most extreme toe misses — a sign that the additional tungsten packed inside the heel and toe was doing its job.

The overall feel of the club was what I’d deem to be muscleback solid with a touch of game-improvement protection. It feels like a solid-construction model at impact, but you don’t get the negative vibrations when it misses out of the toe or heel. The sound at impact was heavy and purposeful. If I didn’t know what I was using, I’d swear it was a forged model. It felt that good.

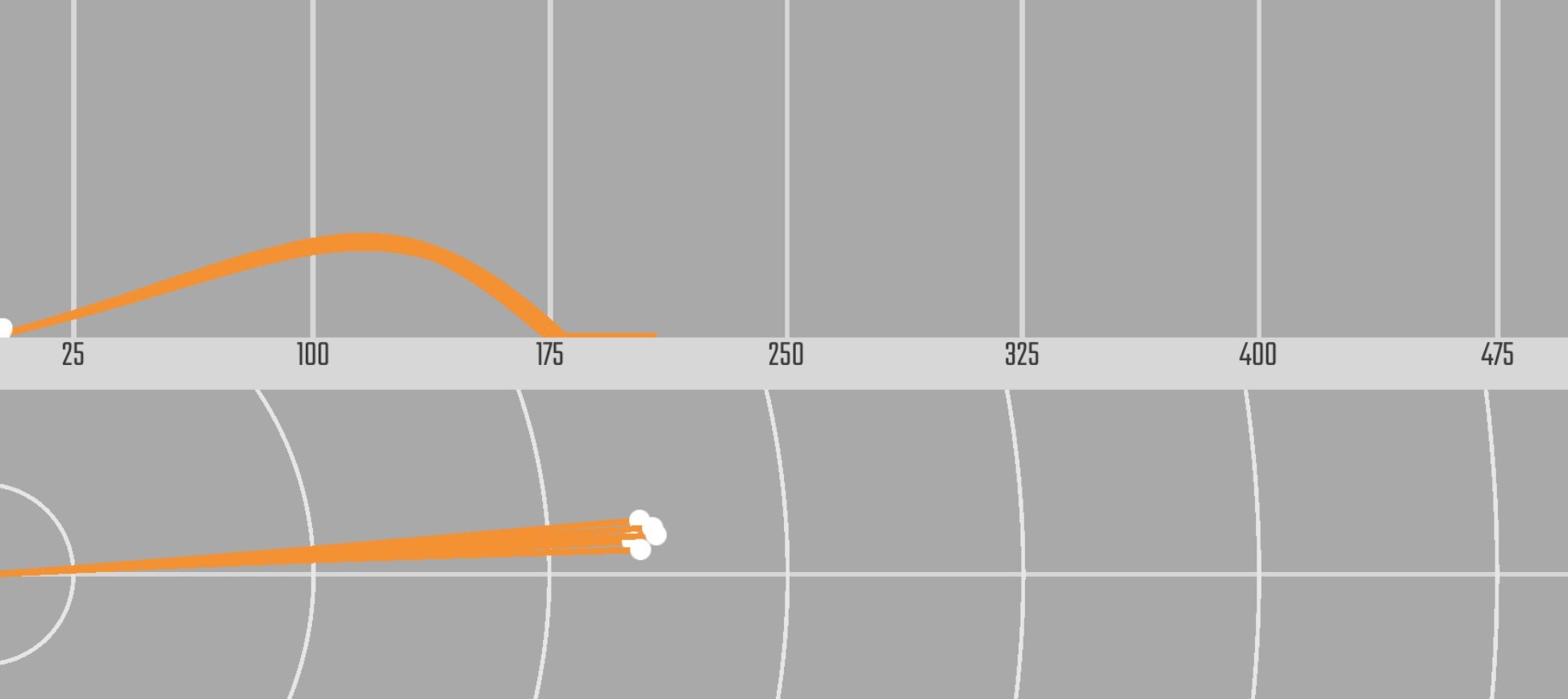

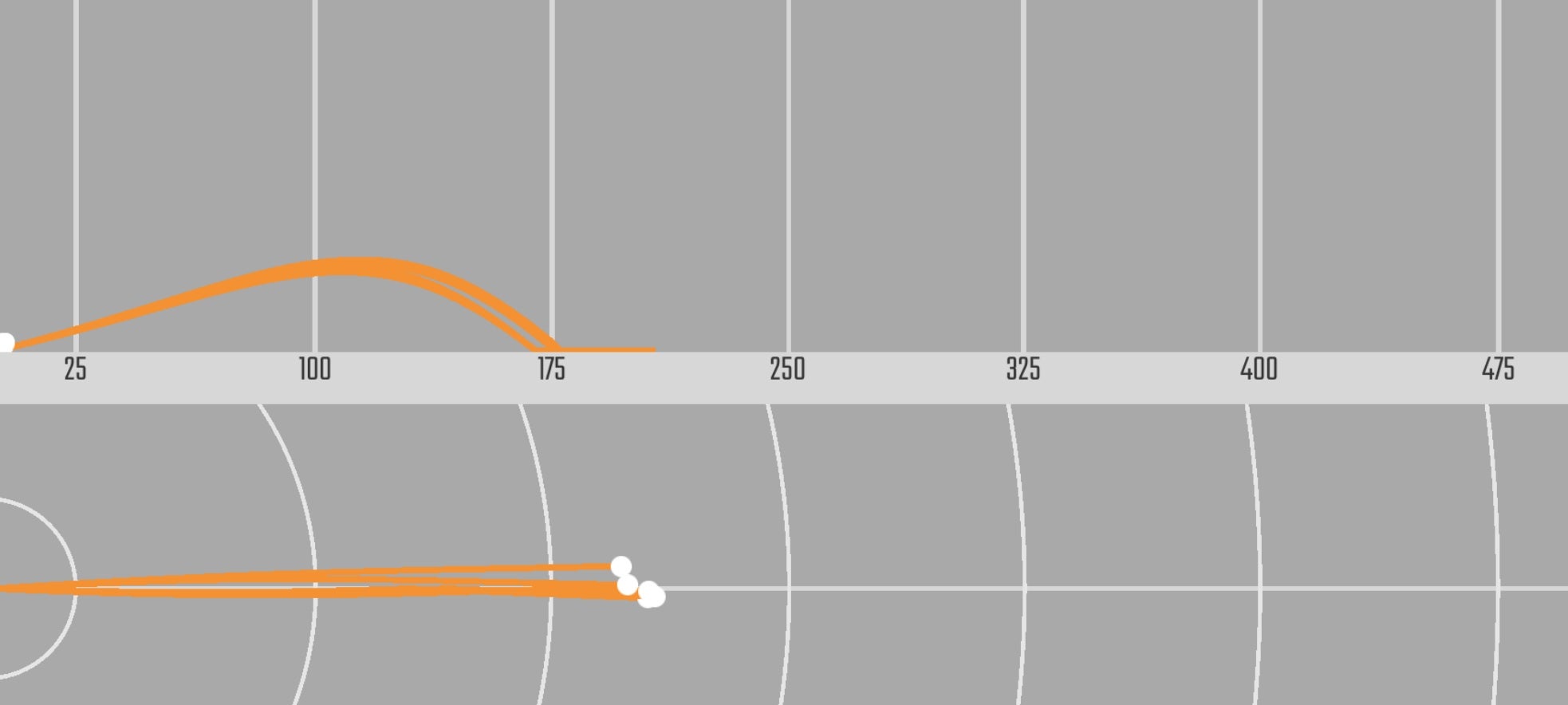

If there was one quibble, it’s that the Limit3d was almost too far left of the target line for my liking, which is saying something considering I like to stay left of the center with my shot shape. The i230 had a tighter overall dispersion and was ever-so-slightly left of center.

I spent nearly a half day building my i230 irons at Ping headquarters, so I expect them to be dialed. Could I get the Limit3d to produce a similar dispersion pattern and shot shape? Possibly. But with only the 7-iron to test, I’m likely going to put an end to testing instead of continuing down the rabbit hole. My biggest fear is finding the iron to be noticeably better and not having the opportunity to test it through the bag.

For the right-handed crew who does have the ability to pick up a full set, I can confirm the Limit3d does a lot of things really well. The overall feel and ball speed retention were seriously impressive, to the point that I’m willing to proclaim they are worth the $3K number.

This feels like the infancy stages of 3D printing in the equipment space, but there’s no question Cobra is already onto something with its initial iron offering.

Want to overhaul your bag for 2024? Find a fitting location near you at True Spec Golf.