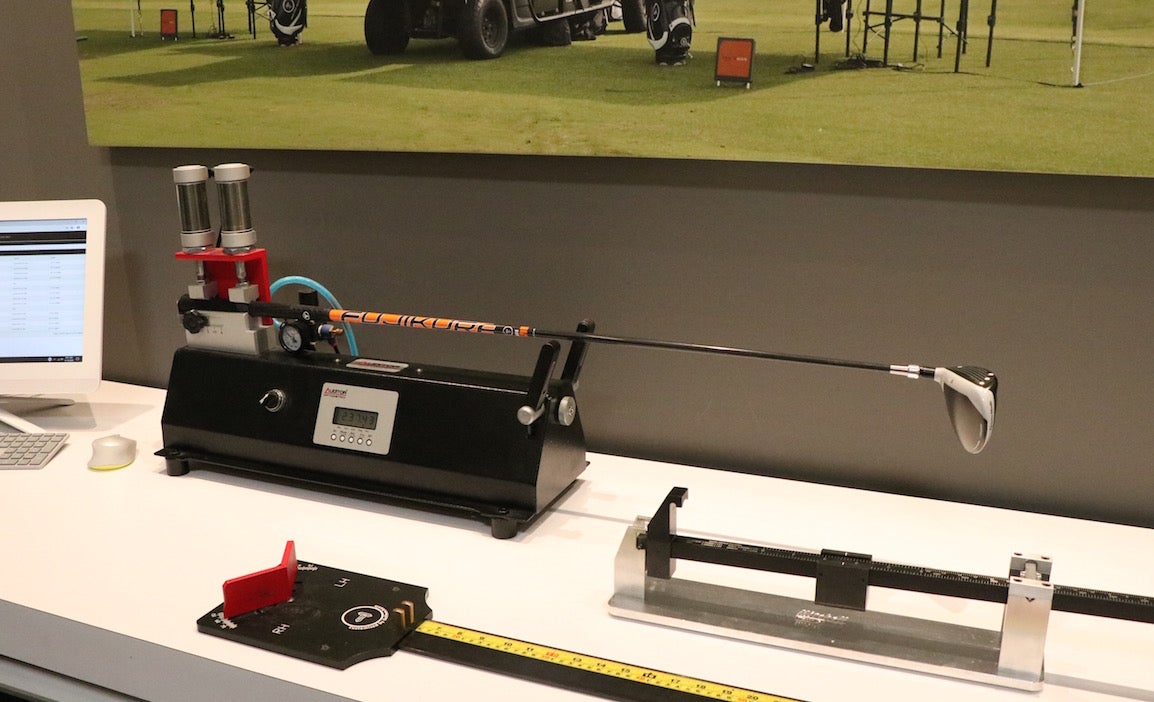

Simply put, CPM stands for “cycles per minute,” which measures the frequency of a golf shaft. To obtain this measurement, a fitter or club builder places the grip end of a golf club into a clamp, then pulls on the tip section of the shaft and releases it to make it oscillate. Golf shafts typically read between 200 (low frequency) and 300-plus (high frequency); the lower-end of the scale would be a shaft that flexes a lot, while the high end of the scale are very stiff shafts.

Many believe that CPM is actually the true flex of a shaft, but after speaking with the expert fitters at GOLF.com’s sister company True Spec Golf, that’s not entirely the case.

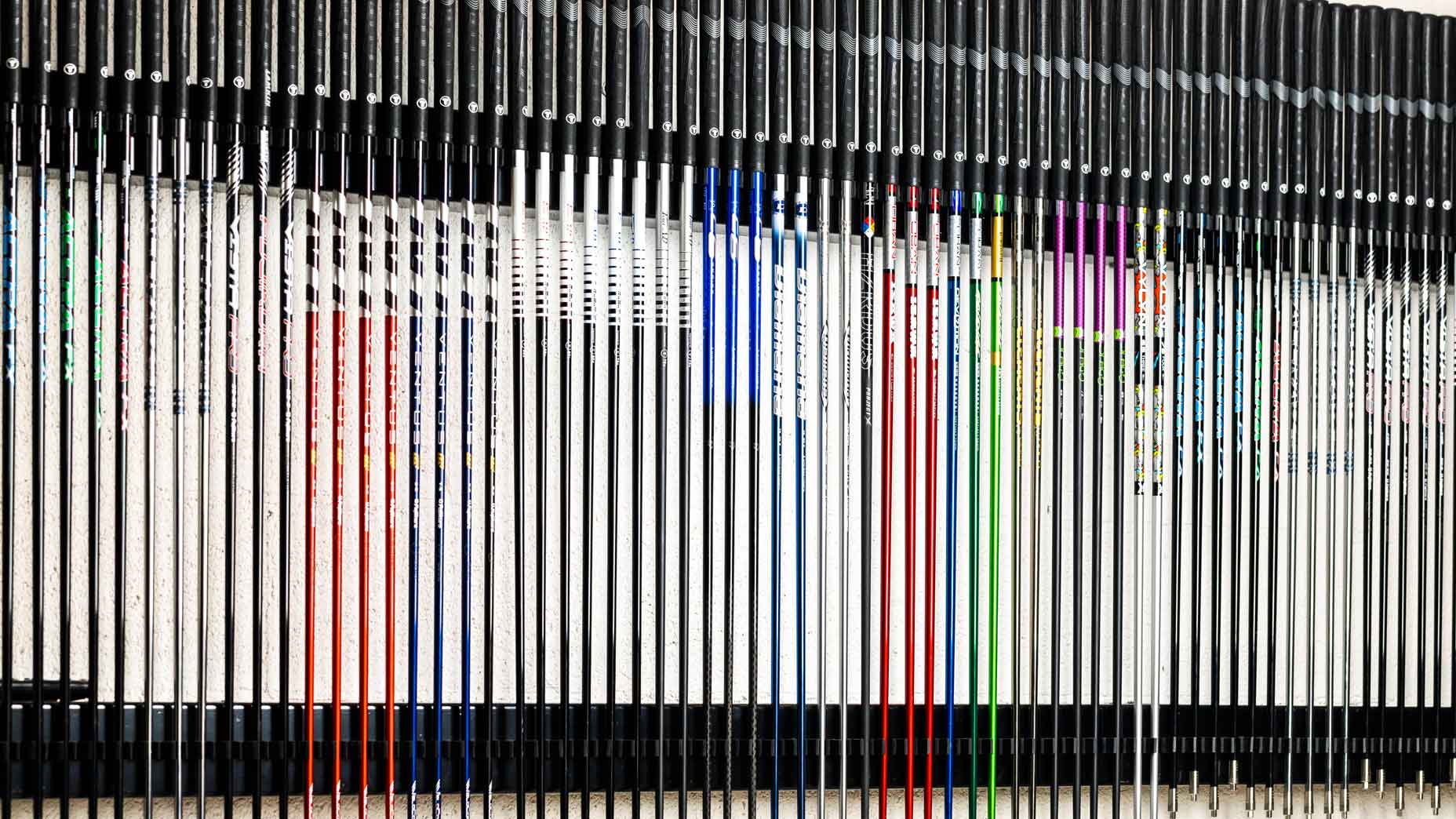

Every shaft company makes shafts differently, and the flexes those companies display are different, too. For example, an “X-flex” of a Graphite Design shaft won’t be the same as an “X-flex” of a Mitsubishi shaft.

Shaft companies measure flexes differently, and their shafts are also made with different materials, wall thicknesses, butt stiffness, bend points, balance points, and a number of other factors. Those factors affect not just how a shaft plays and feels, but how a shaft measures on the CPM machine, as well.

“[Some fitters] think that CPM equals a shaft flex, and that it describes the way a shaft plays, but it doesn’t,” says Tim Briand, Senior Vice President of True Spec Golf. “The perfect example is Nippon Modus iron shafts. A Modus 120X is like a 303 frequency, but Modus 130X is like 336 frequency, even though they’re both X-flexes.”

That being the case, CPM isn’t a perfect way to measure flex.

“[CPM] will put you in the right area of the stadium, but not the right seat,” Briand syas. “If you’re comparing shafts that have the same balance point and the same flex point, then the cycle comparison for flex is fairly accurate.”

So, CPM is truly effective when comparing shafts within the same family or model. By matching CPM, or “frequency matching,” club fitters and builders can ensure that a certain shaft matches the frequency reading of another similar shaft.

Let’s paint a scenario to illustrate how CPM can be used properly.

Say you’re getting a club fitting and you’re absolutely pounding a particular driver setup. You like the way the shaft loads and feels during your swing, and you’re hitting it dead nuts every time. This is the club and shaft combination you want. To ensure that the club you buy plays and feels the same as the club you got fit into, the fitter/builder will measure the CPM of the club you used during the fitting and match that with the club you actually buy.

Additionally, CPM can be used to ensure the proper frequency progression throughout an iron set. Typically, according to True Spec, irons should have about 4 cpm difference per half inch. That means if your 7-iron measures 304 cpm, then your 8-iron should be 308 cpm.

In conclusion, CPM can be a very effective way to match shafts, but not as effective in determining true flex.

To hear more gear insights from Jonathan Wall and True Spec’s Tim Briand, subscribe and listen each week to GOLF’s Fully Equipped podcast: iTunes | SoundCloud | Spotify | Stitcher