Tiger Woods’ arrival at Royal Troon for the 152nd Open Championship confirmed something we’ve known for decades: any gear changes, no matter how big or small, move the needle.

The most recent example came on Monday when Getty Images posted closeup photos of Woods’ TaylorMade MG4 Proto wedges that drew interest from none other than GOLF.com’s own Claire Rogers. While we wouldn’t consider Claire a gearhead, her observation of the rusty appearance of Woods’ scoring tools drew some interesting responses from the commentariat.

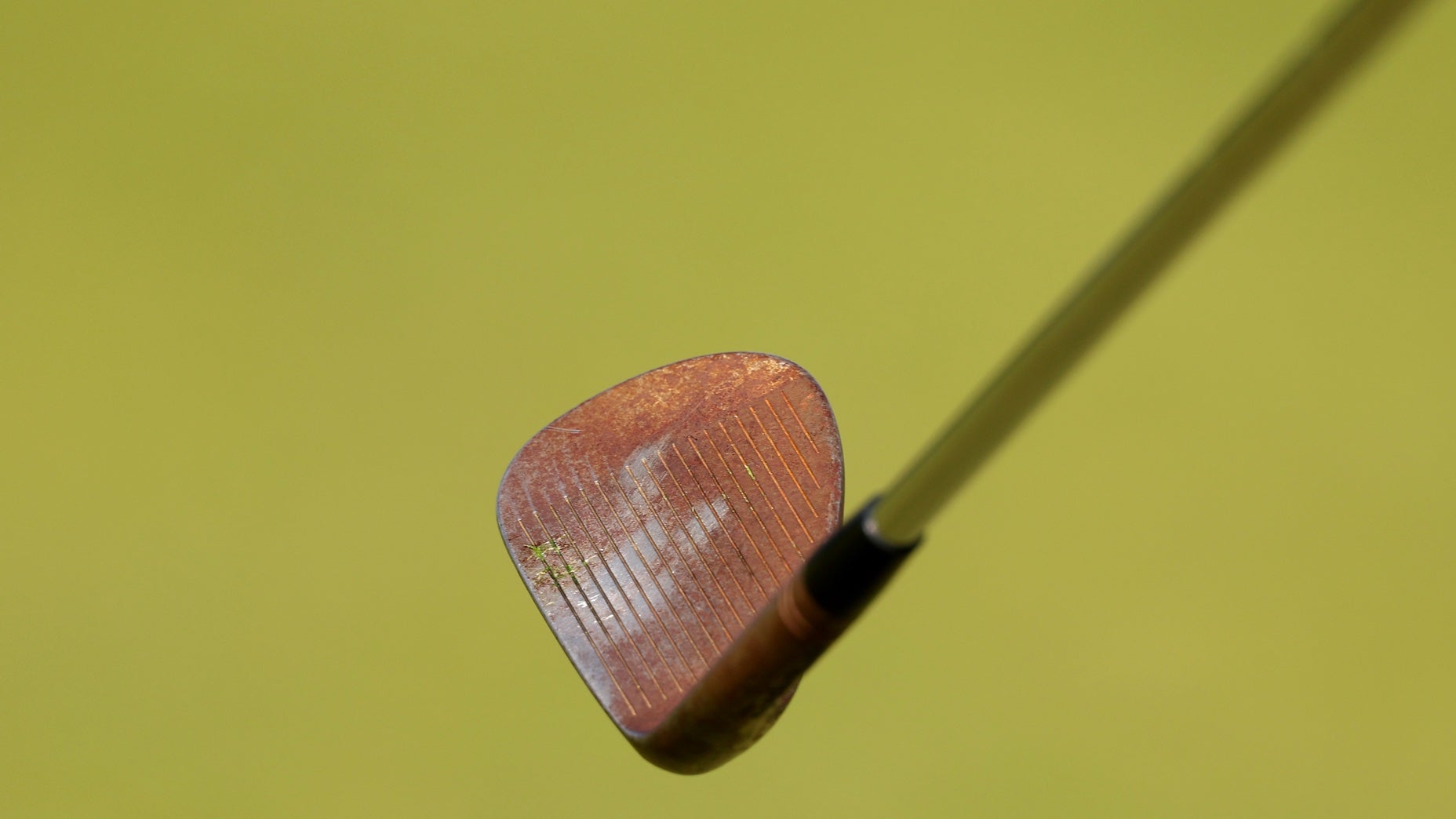

Go back to the U.S. Open and you’ll notice Woods’ wedges were a topic of discussion after he swapped out the 56- and 60-degree TaylorMade MG4s for a prototype version that appeared to have a different sole geometry. Compare the above wedge photo to one from last month and you’ll notice the layer of rust has increased exponentially — to the point you can see where the ball impacted the face. The rust is thick.

So what’s up with the layer of rust covering the head? If you’ve never heard the terms “plated” and “non-plated” before, here’s a quick explainer: a large majority of wedges found on shelves feature a nickel chrome plating over the raw steel that keeps the head and grooves from developing a rusty appearance.

Of course, not everyone wants a plated wedge. For tour pros, removing the plating decades ago made it easier to perform loft, lie and sole modifications on the fly. The only drawback was the layer of rust and patina finish that formed on the raw steel which made it look as if it had been mistreated for years.

Some pros and weekend golfers prefer to keep their tools in pristine condition, but there’s a contingent who swears by the worn, weathered look of a raw head. Some manufacturers have even expanded the list of non-plated offerings in recent years to include certain iron models. The most recent set that comes to mind is Callaway’s Apex MB Raw.

If anything, the layer of rust covering Woods’ wedges confirms he doesn’t mind the worn look. He prefers it. Removing the plating can also make the wedge feel softer at impact, but those are the only two things separating plated and non-plated wedges.

You heard me right: the rust doesn’t provide a noticeable performance benefit.

In our own version of equipment MythBusters, we put a non-plated 56-degree wedge to the test against a plated version, with the help of Gene Parente’s Golf Laboratories swing robot, to see if a noticeable spin difference exists. The non-plated wedge was soaked in water for a week until a significant layer of rust developed on the head. (Like the layer covering Woods’ wedge.)

“The water was looking pretty orange-ish,” Parente said. “You could see it was pretty nasty looking.”

From there, both wedges were hit at 85 miles per hour out of the same center impact location to compare numbers. Even though the non-plated wedge had a rusty face, it still produced nearly identical numbers to the chrome version at roughly 10,000 RPMs. The launch angle, ball speed and total distance were almost the same as well.

“They were within 45 RPMs of each other, which is statistically insignificant,” Parente said. “They look different. But from a launch monitor perspective, from a distance perspective, everything was practically the same.”

What does this tell us about today’s wedges? Groove technology makes a world of difference. In the end, the only noticeable difference you’ll find with a non-plated wedge is a softer feel and grooves that’ll wear out faster due to the lack of plating.

That might come as a disappointment to some, but it’s important to set the record straight on rusty wedges, especially those belonging to the G.O.A.T.

Want to overhaul your bag for 2024? Find a fitting location near you at True Spec Golf.