Anyone who has ever used a Par Aide ball washer has had the thought, What, exactly, is going on in there? (And it is most likely a Par Aide—the St. Paul, Minn., company, founded in 1955, dominates the market and has sold hundreds of thousands of the gizmos in more than 70 countries worldwide.)

It’s always a fleeting thought, since the thing’s inner workings remain as hidden and unknowable as the machinations of the golf gods…until now. Turns out that a ball washer’s machinery, while fairly straightforward, contains thoughtful engineering that deserves our respect no less than our golf ball deserves a good cleansing—and needs one, too, for all of its aerodynamic qualities to work as they should. But that’s a “How It Works” for another day. In the meantime, scrub-a-dub-dub.

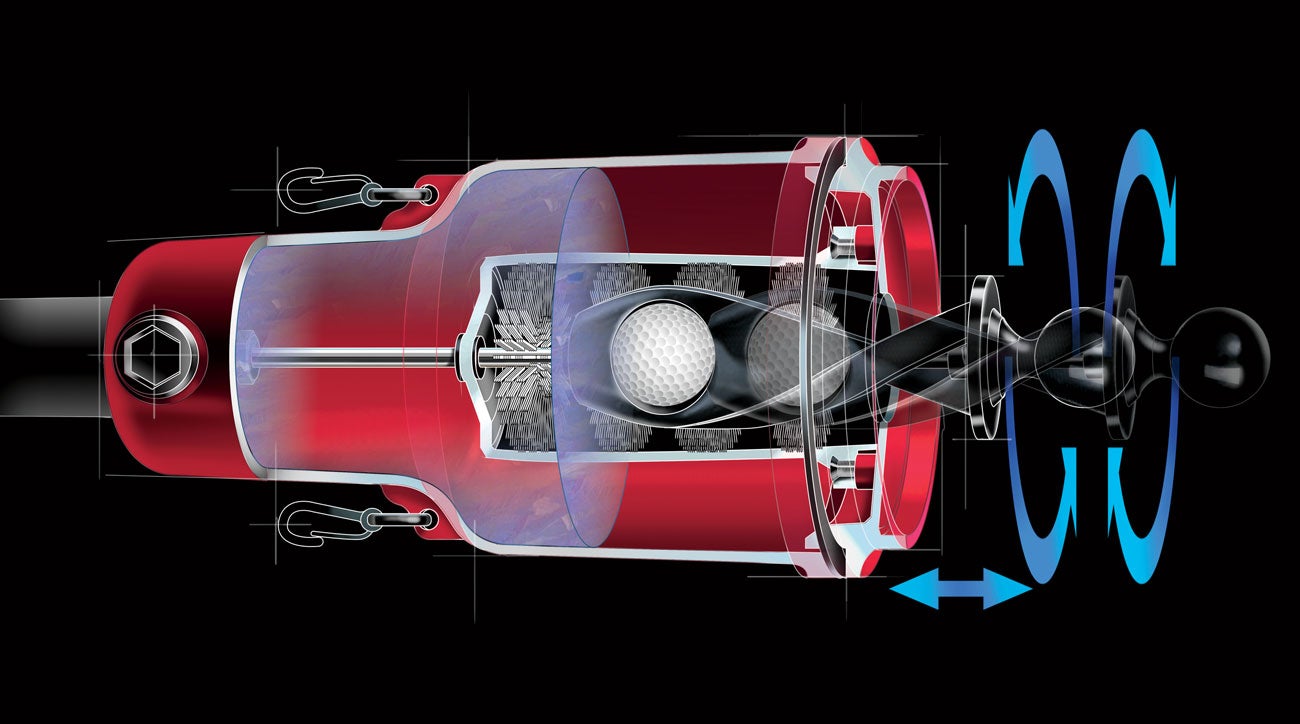

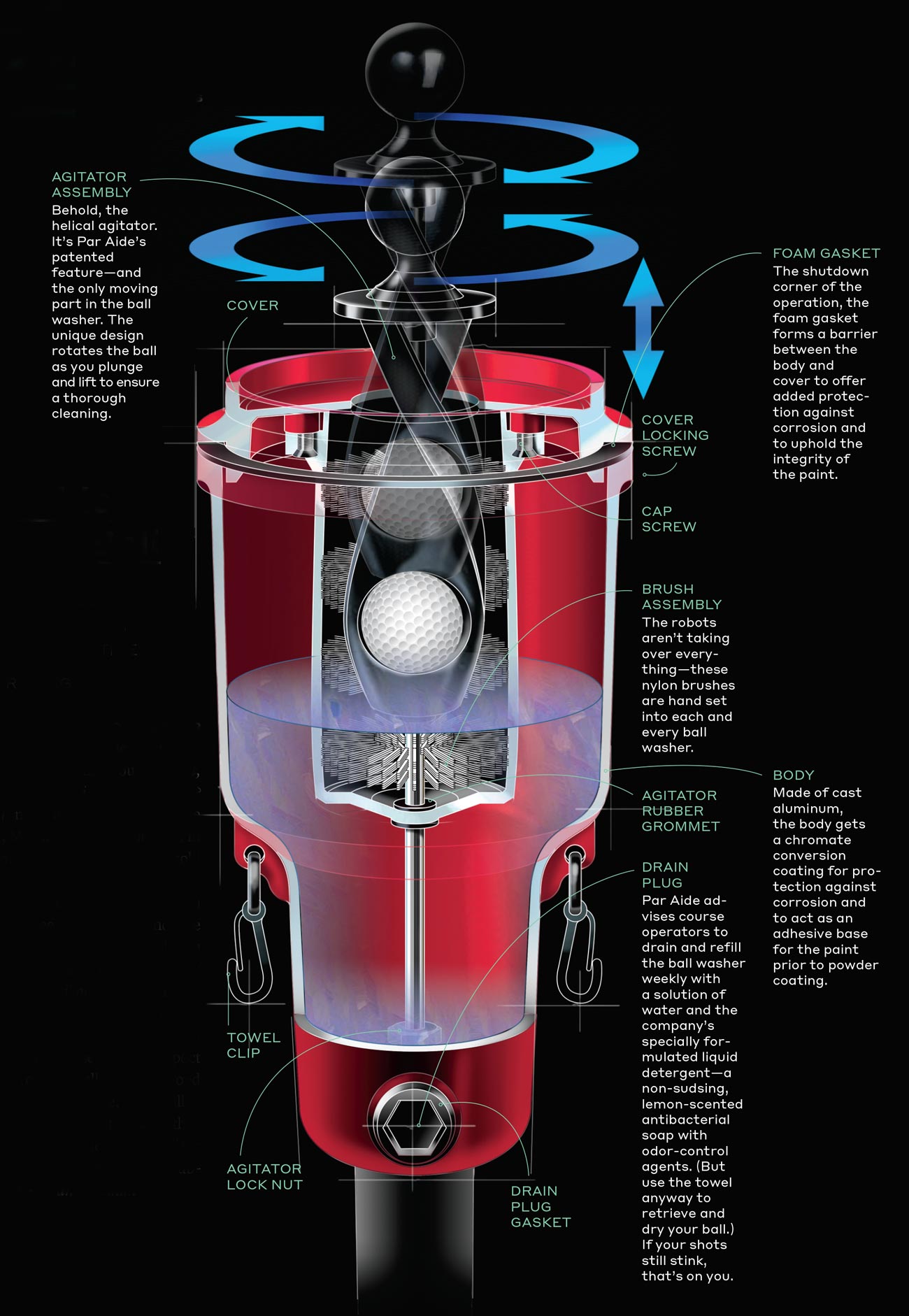

AGITATOR ASSEMBLY

Behold, the helical agitator. It’s Par Aide’s patented feature—and the only moving part in the ball washer. The unique design rotates the ball as you plunge and lift to ensure a thorough cleaning.

FOAM GASKET

The shutdown corner of the operation, the foam gasket forms a barrier between the body and cover to offer added protection against corrosion and to uphold the integrity of the paint.

BRUSH ASSEMBLY

The robots aren’t taking over everything—these nylon brushes are hand set into each and every ball washer.

DRAIN PLUG

Par Aide advises course operators to drain and refill the ball washer weekly with a solution of water and the company’s specially formulated liquid detergent—a non-sudsing, lemon-scented antibacterial soap with odor-control agents. (But use the towel anyway to retrieve and dry your ball.)

If your shots still stink, that’s on you.

BODY

Made of cast aluminum, the body gets a chromate conversion coating for protection against corrosion and to act as an adhesive base for the paint prior to powder coating.

To receive GOLF’s all-new newsletters, subscribe for free here.