These azalea-themed golf balls will get you in the Masters spirit

These azalea-themed golf balls will get you in the Masters spirit

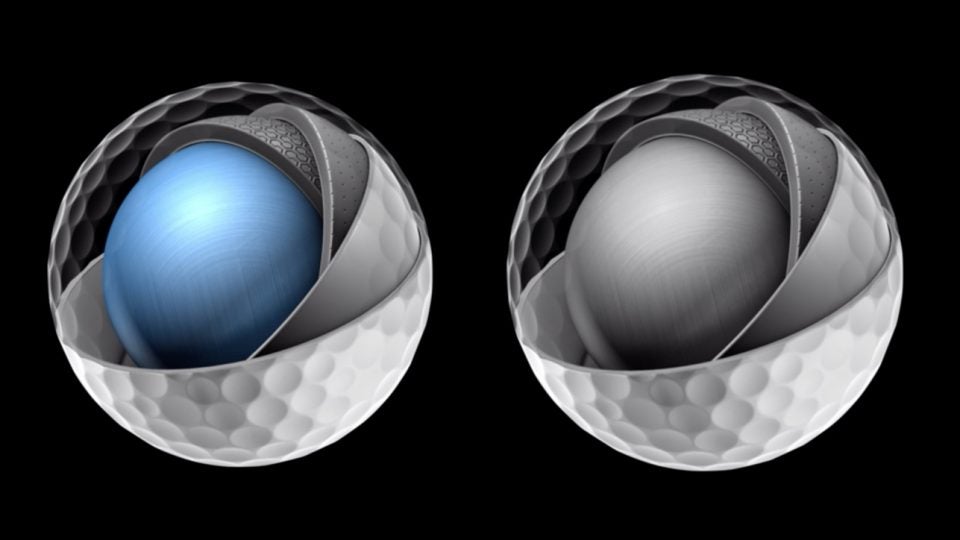

The core in TaylorMade’s TP5 golf ball is an engineering marvel

At the center of the popular TaylorMade TP5 golf ball is a polybutadiene inner core, comprised of the lowest-compression material TaylorMade employs in its ball line. It’s a soft rubber material that allows the ball to sit on the clubface longer to decrease spin and enhance feel. Concealing the inner core is an outer core made up of a stiffer, more resilient rubber that helps reduce spin, particularly at the top of the bag.

From that point forward, each layer (mantle, mantle, cover) gets progressively firmer in an effort to ramp up speed and reduce drag. The mantle layers (polymers and hard resin blends) are sandwiched between the outer core and cover, producing a springlike effect that transfers energy efficiently from club to ball.

“You can’t do the same thing with a four-cylinder car that you can with an eight,” says Mike Fox, TaylorMade’s category director, golf balls. “That’s why we need five layers instead of just three. It gives us that blend of distance and spin around the green. Remove even a single layer and you sacrifice performance in one of those areas.”

A cast urethane cover caps the construction. It’s soft enough to allow clubface grooves to grip the ball for ample greenside spin, but due to the firmer inner layers, it reduces spin when it comes to the woods and scoring clubs. It’s golf’s version of a Swiss Army knife.

ADVERTISEMENT

To receive GOLF’s all-new newsletters, subscribe for free here.

ADVERTISEMENT